Industrial Environment services

Following are our environmental services :-

- Work place monitoring ( Form No-37 )

- NOC from GPCB.

- Consent to operate & establishment (CCA & CTE) .

- EC clearance.

- Monitoring and analysis of water ,waste water ,air, ambient ,solid waste etc.

- Environment Audit

- Treatability study

- Operation and maintenance

- Installation and commissioning of ETP,STP & packaged waste water treatment plant

- Environment filling, statements, returns etc.

- Liasioning.

- Trouble shooting of ETP,STP

- CGWA work

- Water audit

- Effluent Treatment Plant

We undertake Effluent Treatment Plant projects from Concept-to-Commissioning on turnkey basis. Use of latest technologies at the most competitive price is offered, so the industry get maximum benefit of the technology, which in turn ensures compliance to the environmental norms. The plants are designed for auto or manual operation with latest technology system as desired by the customer.

The plants are custom designed based on the effluent characteristics, desired degree of treatment and availability of land.

- Sewage Treatment Plant-Picture

Sewage Treatment is the process of removing contaminants from wastewater generated primarily from industry domestic effluent as well as household activities.

The plants are offered considering the mode of disposal, point of reuse and operational requirement. We also provide combined sewage and effluent treatment plants enhancing the biological system.

We provide Sewage Treatment Plants those are economical and easy to operate.

Civil Construction as well as shop fabricated in MSEP or MSFRP material with an option of manual / auto operation can be provided as per requirement.

- Packaged waste water treatment plant for effluent and sewage treatment plant:

We provide skid mounted package wastewater treatment plants of different capacities for effluent and sewage treatment.

The selection of a packaged wastewater treatment plant offers the user a pre-engineered and pre-fabricated method of treating wastewater.

MOC offered are MSEP and MSFRP based on the life span requirement desired by the customer.

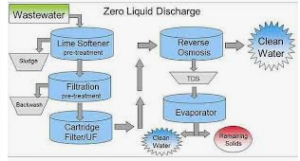

- Zero Liquid discharge:

Zero Liquid Discharge (ZLD) scheme for separation of aqueous waste to its water and solids components wherein the water is reused and solids are recovered as byproducts or disposed as waste.

ZLD enables the industry to overcome the environmental constraints of water scarcity, strong enforcement of environmental regulations, non-availability of disposal point or land lock area, highly polluting industrial activity, industrial effluent having very high TDS &/or organic matter, limited hydraulic capacity of ETP and non-complaint ETP.

ZLD benefits the industry by reducing fresh water demand, generates makeup water, reduces effluent discharge thereby reducing water pollution, reduces cost of disposal at common infrastructure, improve efficiency of effluent treatment through separation of salts and residual solvents, recovery of valuable byproducts thereby reducing the payback period etc.

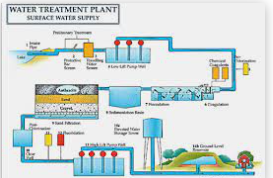

- Water treatment plant

It is process that makes water acceptable for a specific end-use that maybe drinking and/or industrial. Water treatment removes contaminants or reduces their concentration so that the water becomes fit for its desired end-use.

We provide services for industrial sector based on Pressure Filtration, Membrane Filtration and Softening from concept-to-commissioning on turnkey basis. The plants are custom designed based on the source, characteristics and desired degree of treatment.

The plants are designed for the auto or manual operation withPLC – HMI based system as per client requirement.

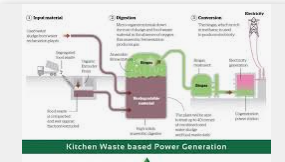

- Waste to energy:

It is the process of generating energy in the form of heat and/or electricity from organic waste.

We produce heat directly through combustion, or produce a combustible fuel commodity, such as methane, methanol, ethanol or synthetic fuels.

- Environmental Clearance

- Environmental Audit& water audit

- Enviro legal services

- Sustainability, green audit

- Troubleshooting of ETP,STP etc.

- CGWA permission

We provide services as per industries requirement pertaining to Environmental Clearance, Audit, Consents and Returns.

- Environment Clearance

We provide services on entire scope of Environmental Impact Assessment (EIA) viz. screening, scoping, baseline monitoring, impact evaluation, preparation of Environmental Management Plan (EMP), public consultation and presentation for appraisal etc.

- Environmental Audits& Water audits:

Environmental audit is a management tool comprising of a systematic, documented, periodic and objective evaluation of Environment management systems.

We also carry out EMS adequacy study to certify the Environmental Management System (EMS) , green audit and sustainability audit for your plant.

Water auditing is a method of quantifying water flows and quality in simple or complex systems, with a View to reducing water usage and often saving money on otherwise unnecessary water use.

- Enviro-Legal services:

We provide assistance in obtaining Enviro-Legal clearances from SPCB. Enviro-legal clearances include:

·Consent to Establish (CTE) / No Objection Certificate (NOC)

.Consent to Operate (CTO) / Consolidated Consent And Authorization (CCA)

.Clearance from Coastal Regulation Zone (CRZ)

.Environmental Statement (Form V)

.Hazardous Waste Details (Form III and Form IV)

.Monthly Patrak and filling returns

.Water audit and impact assessment

.Rain Water Harvesting (RWH)

.Compliance Report Preparation on daily, monthly, half yearly & yearly basis as per requirement

- Sustainability ,green audit

Sustainability audit means the disclosure and communication of environmental, social, &governance (ESG) goals—as well as a company’s progress towards them. Green audit means the purpose of the audit is to identify, quantify, describe and prioritize framework of Environment Sustainability in compliance with the applicable regulations, policies and standards

- Troubleshooting of ETP, STP etc.

The way to cure the sick process of effluent and sewage and to cure with various proven methodology to get andesired characterizeoutput ..

- CGWA permission

Application for Permission (NOC) to Abstract Ground Water for Industrial Use (Application For New NOC) with impact assessment ,water audit & self-compliance submission etc.

- Monitoring & Analysis

- Treatability study& analysis

Our laboratory is equipped with necessary equipment’s, instruments, models and well versed, trained & experienced persons responsible for environmental parameter analysis, applied research and technological development of innovative treatments for wastewater treatment and reuse.

- Monitoring & analysis

We provide monitoring and analytical services to the industries for,

- Water and Wastewater

- Ambient Air

- Stack Emissions

- Hazardous Waste

- Work Place

- Noise

We provide servicesas per requirement n annual rate contract basis and also as per specific requirement of the industry.

- Treatability study &analysis:

We conduct treatability for industrial wastewater treatment as per desired by the industry.

We possess technical knowhow along with laboratory to conduct treatability studies for wastewater treatment.- Microbiological treatability of effluent samples.

- Determination of total microbial count in a sample drawn from the effluent treatment plant

- Establishment of the correlation between MLSS and the total microbial count Biomass development,

- Biological removal of color from

- Monitoring & analysis

We are assisting to cater following advanced technologies to get desired results in your plant.

- Membrane bioreactor

- Sequential Aeration tank

- Moving bed bioreactor

- Activated sludge process

- De-nitrification

- Up flow Anaerobic sludge blanket

- Biogas plant

- Advance oxidation process

- Reverse Osmosis

- Multi effect evaporator

- Agitated thin film dryer

- Membrane Bioreactor

Membrane Bioreactor (MBR) integrating biological degradation of waste products with membrane filtration. It composed of two primary parts, the biological unit responsible for the biodegradation of the waste compounds and the membrane module for the physical separation of the treated water from mixed liquor.

- Sequential Aeration Tank (SAT):

It is a fill-and-draw activated sludge treatment system. It is compact, time oriented and capable of removing nutrients from wastewater. All the processes viz. fill, react, settle and decant are carried out sequentially in same tank.

- Moving Bed Moving Bed Bioreactor (MBBR)

Moving Bed Biofilm Reactor (MBBR) technology use biofilm carriers operating in mixed state within an aerated wastewater treatment basin. Each individual bio carrier increases productivity through providing protected surface area to support the growth of heterotrophic and autotrophic bacteria within its cells. It is this high-density population of bacteria that achieves high-rate biodegradation within the system, while also offering process reliability and ease of operation.

This technology provides cost-effective treatment with minimal maintenance since MBBR processes self-maintain an optimum level of productive biofilm. Additionally, the biofilm attached to the mobile bio carriers within the system automatically responds to load fluctuations.

This processes improve reliability, simplify operation, and require less space than traditional wastewater treatment systems.

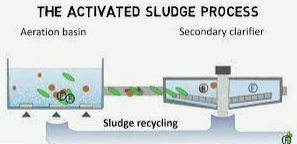

- Activated sludge Process:

It refers to a mass of microorganisms cultivated in the treatment process to break down organic matter into carbon dioxide, water and other inorganic compounds. The activated sludge process has three basic components: 1) a reactor in which the microorganisms are kept in suspension, aerated and in contact with the waste they are treating 2) liquid-solid separation 3) a sludge recycling system for returning activated sludge back to the process. There are many variants of activated sludge processes, including variations in aeration method and in the way the sludge is returned to the process

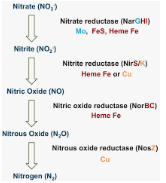

- Denitrification

It is essentially for conversion of nitrate to nitrogen gas. It is a natural process carried out by microorganisms when sufficient oxygen is lacking. Hear using oxygen as the final electron acceptor in metabolism nitrate is used. Denitrification releases nitrogen which escapes as an inert gas to the atmosphere while oxygen released stays dissolved in the liquid and thus reduces the oxygen input needed into the system.

Denitrification as a primary treatment helps reducing ammonia and nitrogen content in the treated effluent at lower operating cost as the oxygen input to the system is reduced.

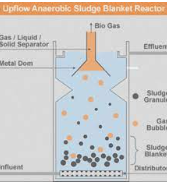

- Up flow anaerobic sludge blanket (UASB):

This technology, is a form of anaerobic digester which is used for wastewater treatment. UASB reactor is a methanogenic (methane-producing) digester that evolved from anaerobic clarigester. UASB uses an anaerobic process whilst forming a blanket of granular sludge which suspends in the tank. Wastewater flows upwards through the blanket and is processed (degraded) by the anaerobic microorganisms. The upward flow combined with the settling action of gravity suspends the blanket. The flow conditions create a selective environment in which microorganisms capable of attaching to each other survive and proliferate. Eventually the aggregates form into dense compact biofilms referred to as “granules”.

Biogas with a high concentration of methane is produced as a by-product, and this may be captured and used as an energy source, to generate electricity for export and to cover its own running power.

- Biogas plant:

It is efficient in removal of SS and BOD. When used as a primary treatment followed by secondary aerobic treatment, it is efficient in removal of BOD, COD and nutrients of high strength effluent at a lower opex. This is a simpler and robust anaerobic treatment.

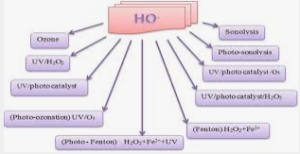

- Advanced oxidation processes (AOPs)

It is a broad sense, are a set of chemical treatment procedures designed to remove organic (and sometimes inorganic) materials from water and waste water by oxidation through reactions with hydroxyl radicals (·OH). This term usually refers more specifically to a subset of chemical processes that employ hydrogen peroxide (H2O2), ozone (O3), and/or UV light.

The AOP procedure is particularly useful for cleaning biologically toxic or non-degradable materials such as aromatics, pesticides, petroleum constituents, and volatile organic compounds in waste water. Additionally, the contaminant materials are converted to a large extent into stable inorganic compounds such as water, carbon dioxide and salts, i.e. they undergo mineralization.

- Reverse osmosis:

It is a process that uses to clean water, for industrial process applications or to convert brackish water, to clean up wastewater or to recover salts from industrial processes.

In reverse osmosis process -like membranes separate purified water from contaminated water. RO is when a pressure is applied to the concentrated side of the membrane forcing purified water into the dilute side, the rejected impurities from the concentrated side being washed away in the reject water. RO can also act as an ultra-filter removing particles such as some micro-organisms that may be too large to pass through the pores of the membrane.

Common membrane materials include polyamide thin film composites (TFC), cellulose acetate (CA) and cellulose triacetate (CTA) with the membrane material being spiral wound around a tube, or hollow fibers bundled together. TFC spiral wound membranes are most used due to its superior strength and durability, higher rejection rates and are more resistant to microbial attack, high pH and high TDS.

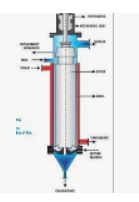

- Multi effect evaporator:

A multiple-effect evaporator is an apparatus for efficiently using heat from steam to evaporate water. In a multiple-effect evaporator, water is boiled in a sequence of vessels, each held at a lower pressure than the last. Because the boiling temperature of water decreases as pressure decreases, the vapor boiled off in one vessel can be used to heat the next, and only the first vessel (at the highest pressure) requires an external source of heat and thus saves energy and overall operational cost.

It is widely used for product concentration and has now been used for recovery of water from wastewater which can be reused for industrial operations thus reducing overall fresh water demand of the industry leading zero liquid discharge and sustainable development.

- Agitated thin film evaporator

Thin Film Dryer is used to dry and collect baggable solids from high TDS solution that comes out of Multi Effect Evaporator after water recovery.

A typical Thin Film Evaporator consists of a tubular heat transfer area with an external heating jacket and a fast-revolving, inner rotor with flexible or rigid wiper elements. The feed product is evenly distributed by the rotor and its wipers over the heating surface, forming a thin liquid film of uniform thickness. This assures excellent heat transfer combined with constant renewal of the product film and provides an even heating and short residence time of the product.